Wood Trusses - Reliability You Can Count On

Over the past 20 years prefabricated roof trusses have become one of the most reliable and cost-effective wood framing options for builders and contractors. Today, prefabricated roof and floor trusses are available at almost every lumberyard in the U.S., including right here at Wilson Lumber.

Used in remodeling, single family construction and multifamily housing, trusses can lower the cost of the project, install quickly, do not require special tools or highly skilled labor, and can significantly reduce the amount of waste on the job site. With these clear and measurable benefits, it makes sense that prefabricated roof trusses have become one of the most common and dependable framing techniques in new construction.

Lower cost

In addition to cost savings, prefabricated trusses can save upwards of 40% in overall installation time, according to Framing the American Dream, a study by the Structural Building Components Association. Trusses are built from shorter lengths of lumber and are manufactured in a facility that has the capability to streamline production, optimize the roof design and minimize waste. This process makes them much less expensive overall than conventional rafter framing. Roof designs such as cross gables and cathedral ceilings can typically be prohibitively expensive. However, because prefabricated truss systems allow for almost any custom roof design and shape imaginable, even difficult roof plans can be cost effective

Faster Installation

Manufactured trusses do a lot to improve the speed of your construction project. Trusses can typically be installed in a single day, which decreases the number of labor days. This also allows the structure to be closed up sooner, protecting the interior from the elements. Because trusses are premanufactured, they can be ordered in advance. Your jobsite package is simply delivered directly to your job site ready to be installed on your schedule.

Increased Span

One often overlooked benefit of prefabricated roof trusses is the freedom they give you to design the interior of a home. Roof trusses can span much longer distances without the need for load bearing interior walls. This frees up your design capabilities and allows you to incorporate more of those open-concept floor plans and features that current home buyers love.

Higher Quality Product

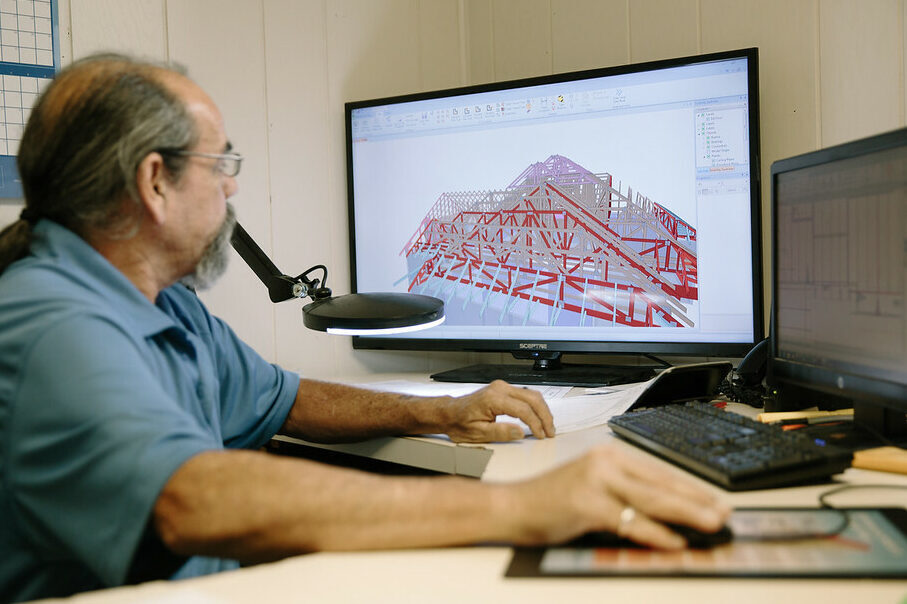

Manufactured trusses are built in a controlled environment using precision machinery, dry lumber and engineered connectors. The lumber is stored inside, away from the elements and in an environment where water and heat can’t warp your products. Prefabricated trusses are precision cut and assembled with specifically engineered connectors. At Wilson Lumber we partner with Alpine, a division of Illinois Tool Works Inc (ITW) and a leader in improving truss manufacturing through innovation, software development, and engineering services. These tools and products combine to produce uncompromised quality and performance.

Engineered Product

Wood trusses are engineered as a job specific package. Each truss is designed with the necessary loads as codes required and optimized for peak performance. Not only are trusses predictable – meaning we know how they will perform even before they are built – they are more stable in cost because they require 25% less lumber when compared to the stick framed alternative. Every truss manufactured is backed by an engineer guaranteeing its performance.

Your imagination is the limit when building with roof trusses. By utilizing state-of-the-art design software, Wilson Lumber truss designers can create all types of roof and ceiling profiles for a variety of project types, including assisted living facilities, churches, banks and more. No project is too big!

Contact Us

Our experts will help you design and build a cost effective and high-quality premanufactured truss system for your next project.